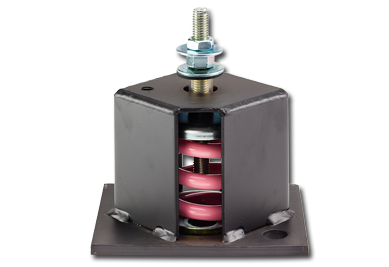

MS Series Isolators, combine our open spring mountings within a rugged welded seismically rated steel housing. To minimize, the code required seismic loads on the isolated equipment, the housing is designed to limit equipment motion to ¼" in horizontal directions due to wind or seismic loads. The MS style isolator has internal spring adjustment. The top housing incorporates seismic restraint bolts that pass through the lower housing and are protected in all directions by an elastomeric bushing. Combined, the restraint bolts and bushings act as the internal snubbing devices for the isolator. To achieve accurate installation heights, VMC Group has incorporated an installation spacer between the lower and upper housing.

After the equipment is installed and the isolators are properly adjusted, there will be no difference between the installed and operating heights. Mechanical equipment can be positively attached to the top housing by utilizing the pre-drilled bolt holes or by welding directly to the housing. Low frequency T-Series steel springs are located within the housing and are seated in an elastomeric acoustical cup that provides high frequency attenuation and eliminates metal-to-metal contact.

The spring and cup design allows for easy replacement or changing of springs when required and all springs are color-coded for ease of identification in the field. The lower housing incorporates an oversized base plate that spreads the anchor bolt over a wider area - this is specifically designed to increase seismic restraint capability. As an additional benefit, ease of installation is also achieved by allowing easy access to the anchor bolts. These isolators are designed for installations in either concrete or steel and the base plates are pre-drilled with mounting holes to accommodate attachment to MS Series Isolators. MS Isolators are available with 1" through 5" deflection springs. Each style of mount has a load range of 50 lbs. to 68,000 lbs.

Features & Benefits

- Rugged steel housing serves as blocking during equipment erection

- Housing offers no difference in elevation between installed and operating height

- Installation spacer ensures accurate installation height and adjustment

- Top plate may be welded or bolted to equipment, allowing flexible design options

- Housings are identical in height within each series

- Easily accessible bolt holes permit simplified installation

- Elastomeric acoustical cup eliminates high frequency vibrations

- Color-coded springs permit ease of identification of load capacity

- Internal adjustments, with interchangeable springs

- For use in most seismic and wind applications

- Rugged steel housing is designed to handle high wind and seismic forces

Applications

- HVAC and electrical equipment

- Air handling units

- Cooling towers

- Chillers

- Engine gensets

- Seismic

DOWNLOADS

Submittal Drawings

- 1" Deflection

- Model M2S-1C 500-1040 lbs. Vibration isolator with integral seismic restraint and internal adjustment for 1 inch deflection_rev.10

- Model MS-1C 50-520 lbs. Vibration Isolator with integral seismic restraint and internal adjustment 1 inch deflection_rev. 12

- Model M2S-1E 3400-6500 lbs. Vibration isolator with integral seismic restraint and internal adjustment for 1 inch deflection_rev.11

- Model M6S-1E 6000-19500 lbs. Vibration isolator Seismic restraint 1 inch deflection_rev.7

- Model M9S-1E 9000-29250 lbs. Vibration isolator seismic restraint 1 inch deflection_rev.7

- Model MS-1E 195-3250 lbs. Vibration isolator with integral seismic restraint and internal adjustment 1 inch deflection_rev.11

- Model M4S-1E 4000-13000 LBS. Vibration isolator seismic restraint 1 inch deflection_rev.3

- 2" Deflection

- Model M2S-2D 870-3280 lbs. Vibration Isolator with Integral Seismic Restraint and Internal Adjustment for 2 inch deflection_rev.10

- Model MS-2D 75-1640 lbs. Vibration Isolator with Integral Seismic Restraint and Internal Adjustment 2 inch deflection_rev.9

- Model M2S-2E 2000-5400 lbs. Vibration isolator with integral seismic restraint and internal adjustment for 2 inch deflection_rev.12

- Model M4S-2E 4000-10800 lbs. Vibration Isolator with Integral Seismic Restraint and Internal Adjustmnet for 2 inch deflection_rev. 3

- Model MS-2E 80-2700 lbs. Vibration isolator with integral seismic restraint and internal adjsutment 2 inch deflection_rev. 10

- Model M6S-2E-6000 Thru 16200 lbs. Vibration Isolator With Integral Seismic Restraint and Internal Adjustment For 2 Inch Deflection_rev.2

- Model M9S-2E-9000 Thru -24300 lbs. Vibration Isolator with Integral Seismic Restraint and Internal Adjustment for 2 Inch Deflection_rev.3

- Model M12S-2F 1200-26400 lbs. Vibration isolator Seismic restraint 2 inch deflection_rev.5

- Model M4S-2F 1700-8800 lbs. Vibration Isolator Seismic restraint 2 inch deflection_rev.5

- Model M6S-2F 9000-13200 lbs. Vibration isolator Seismic restraint 2 inch deflection_rev.5

- Model M9S-2F 9000-19800 lbs. Vibration isolator seismic restraint 2 inch deflection_rev.5

- 3" Deflection

- Model M2S-3C 150-2330 lbs. Vibration isolator with internal seismic restraint and internal adjustment for 3 inch deflection_rev. 7

- Model MS-3C 75-1165 lbs. Vibration isolator with integral seismic restraintand internal adjustment 3 inch deflection_rev.3

- Model M9S-3C-675 Thru -10485 lbs. Vibration Isolator with Integral Seismic Restraint and Internal Adjustment for 3 Inch Deflection_rev.1

- Model M2S-3D 1600-4070 lbs. Vibration isolator with integral seismic restraint and internal adjustment 3 inch deflection_rev.4

- Model MS-3D 800-2035 lbs. Vibration isolator with integral seismic restraint and internal adjustment 3 inch deflection_rev.4

- Model M2S-3E 3200-7000 lbs. Vibration Isolator with Integral Seismic Restraint and Internal Adjustment 3 Inch Deflection_rev.6

- Model MS-3E 1600-3500 lbs. Vibration isolator with integral seismic restraint and internal adjustment 3 inch deflection_rev.4

- Model MS-3E 1600-3500 lbs. Vibration Isolator with Integral Seismic Restraint and Internal Adjustment 3 inch Deflection_rev.6

- Model M4S-3E 6400-14000 LBS. Vibration Isolator with Integral Seismic Restraint and Internal Adjustment 3 Inch Deflection_rev.10

- Model M6S-3E 9600-21000 LBS. Vibration Isolator with Integral Seismic Restraint and Internal Adjustment 3 Inch Deflection_rev.1

- 4" Deflection

- Model MS-4C 65-1460 lbs. Vibration isolator with integral seismic restraint and internal adjustment 4 inch deflection_rev.3

- Model M2S-4C 130-2920 LBS.Vibration Isolator with Integral Seismic Restraint and Internal Adjustment 4 inch deflection_rev.4

- Model M2S-4D 3530-10420 lbs. Vibration Isolator With Integral Seismic Restraint And Internal Adjustment 4 Inch Deflection_rev.6

- Model MS-4D 1765-5210 lbs. Vibration Isolator with integral seismic restraint and internal adjusment 4 inch deflection_rev.5

- Model M4S-4D-7060-20840 Vibration Isolator with Integral Seismic Restraint and Internal Adjustment for 4 inch Deflection_rev.3

- 5" Deflection

- Model M2S-5C 500-4600 lbs. Vibration isolator with integral seismic restraint and internal adjustment 5 inch deflection_rev.4

- Model MS-5C 250-2300 lbs. Vibration isolator with integral seismic restraint and internal adjustment 5 inch deflection_rev.4

- Model M2S-5D 5400-11350 lbs. Vibration isolator with integral seismic restraint and internal adjustment 5 inch deflection_rev.4

- Model MS-5D 2700-5675 lbs.Vibration isolator with integral seismic restraint and internal adjustment 5 inch deflection_rev.4

- Model M4S-5D Series Vibration Isolator with Integral Seismic Restraint and Internal Adjustment for 5 inch Defelction_rev.6

RELATED SERVICES

The engineers we employ hold the highest industry-recognized credentials in structural analysis, elastomer development and system dynamics.

We are the first ISO accredited PCA ISO-17065, third-party certification body for special seismic certification of non-structural building components and their mounting configurations by the ICC’s International Accreditation Service.

We are the only ISO 17025:2005 Accredited Seismic Simulation Test Laboratory with a triaxial shake table owned and operated by California licensed Structural engineers.

Testing Services Update

DCL now offers Nuclear Qualification and Testing services.

In partnership with Greenberry Industrial, we now offer testing services that meet the requirements of ASME NQA-1.